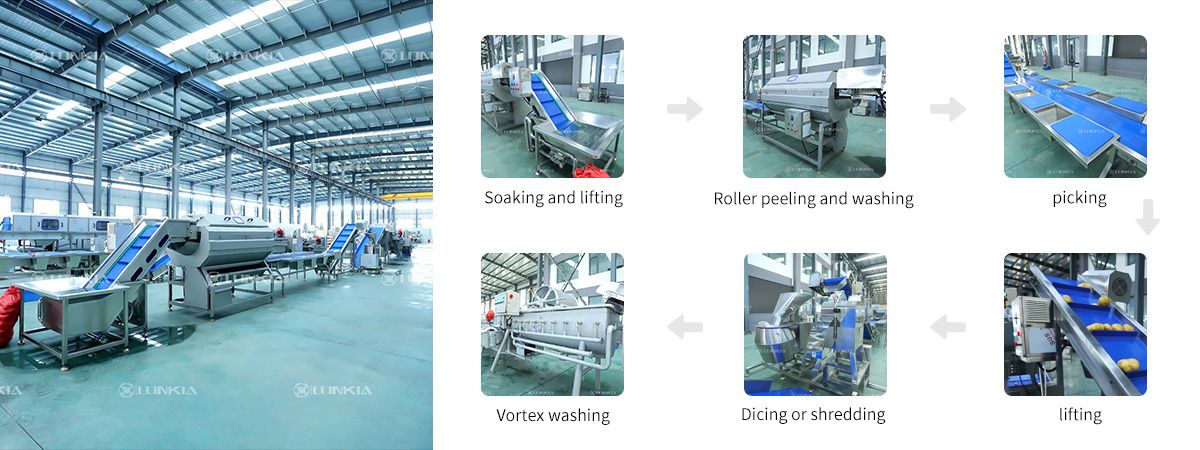

The vegetable Potato processing line is a fully automated solution designed for the efficient cleaning, peeling, cutting, and washing of potatoes. This line integrates advanced washing and cutting technologies to ensure high-quality diced or julienne potatoes, preserving their natural texture and color. Equipped with an ozone-enhanced vortex washing system, it effectively removes surface dirt, bacteria, and residual starch, ensuring food safety compliance. This energy-efficient solution is ideal for frozen potato products, pre-cut vegetables, and foodservice industries.

Processing Output: 300KG-5000KG/H (Customizable)

1

1

Soaking and Lifting

2

2

Roller Peeling and Washing

3

3

Picking

5

5

Lifting

6

6

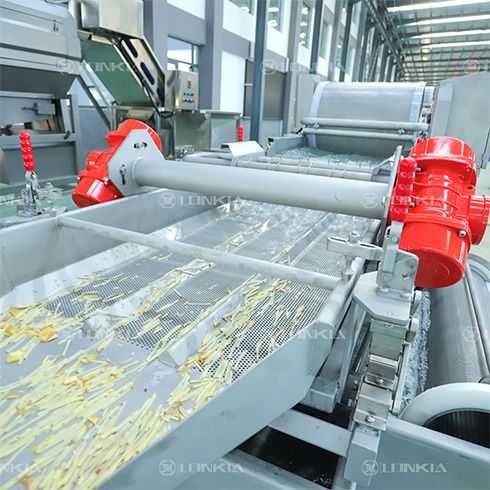

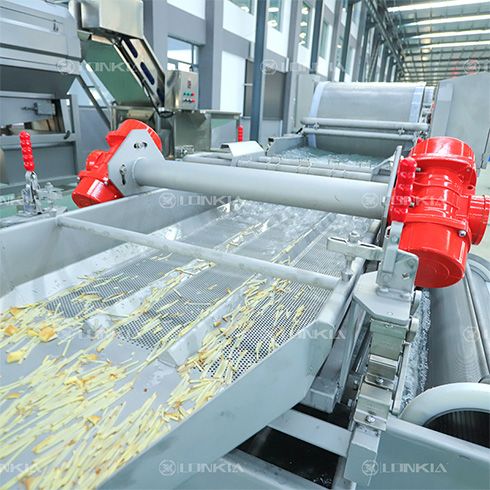

Dicing or Shredding

7

7

Vortex Washing

Feel free to contact us to getting offer and more information about our vegetable Potato processing line.

Can be expanded at any time to accommodate higher capacities and meet individual requirements

Our potato processing line is widely used in vegetable processing plants, food manufacturing facilities, central kitchens, and supermarket distribution centers.

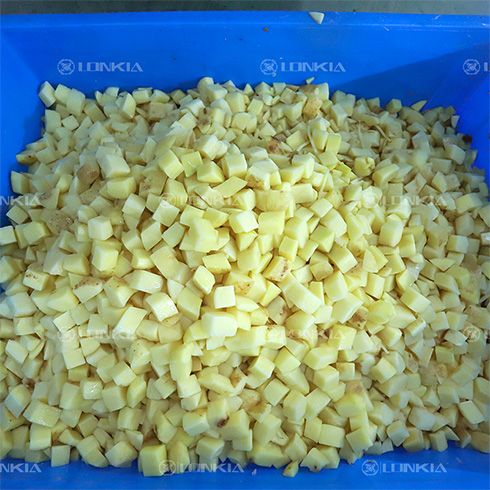

Diced Potatoes

Diced Carrots

Diced Cucumber

Shredded potatoes

Shredded carrots

Diced white radish

Shredded Beets

Diced Sweet Potatoes

Have a question on equipment, pricing, parts, service or anything else? We’re here to help.

Contact Us