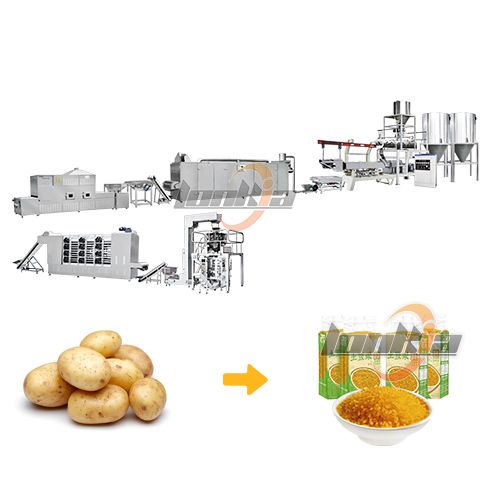

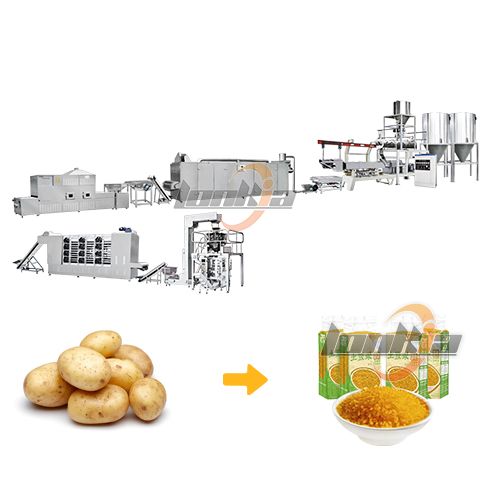

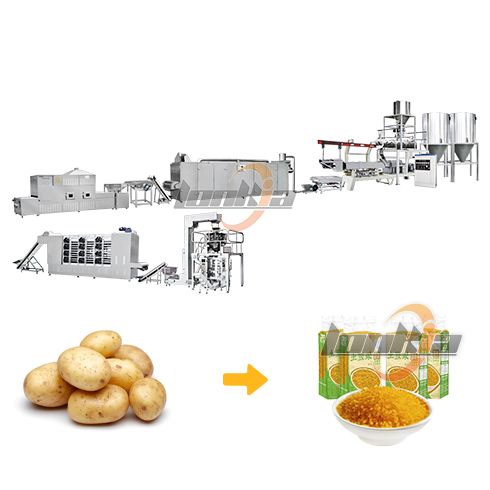

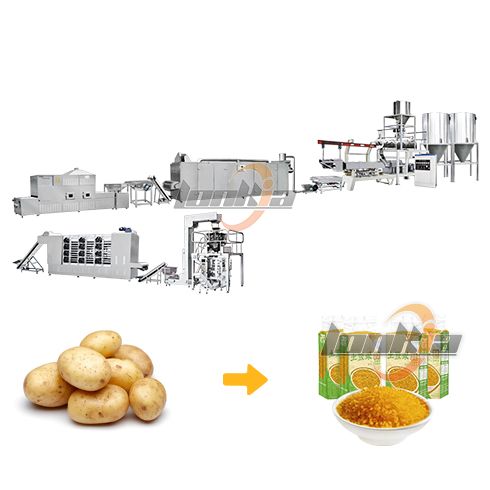

“Potato Rice” is a starch-based rice-like product made from fresh potatoes using advanced processing technology. This innovative product offers a new way to transform surplus potato yields into a staple food, contributing to global food security. By converting excess potato capacity into high-value products, this technology provides a forward-looking solution for food system resilience and is especially suited for upgrading industrial chains in major potato-growing regions.

Processing Capacity: 600-800KG/H

Feel free to contact us to getting offer and more information about our Potato Rice Production Line.

Can be expanded at any time to accommodate higher capacities and meet individual requirements

Food Security Advantage: Helps diversify staple food sources, aligning with global food safety and sustainability strategies.

Utilization of Surplus: Turns abundant raw potatoes into value-added products, reducing post-harvest waste.

High Automation: Streamlined operation with minimal manual intervention ensures consistent product quality.

Flexible Capacity: Modular design allows adjustment to different production scales.

Energy Efficiency: Optimized steam and electric heating systems significantly reduce energy consumption.

Market-Ready Output: The final potato rice product is uniform, shelf-stable, and ready for commercial distribution.

Potato Rice

Potato Rice

Potato Rice

Potato Rice

Have a question on equipment, pricing, parts, service or anything else? We’re here to help.

Contact Us