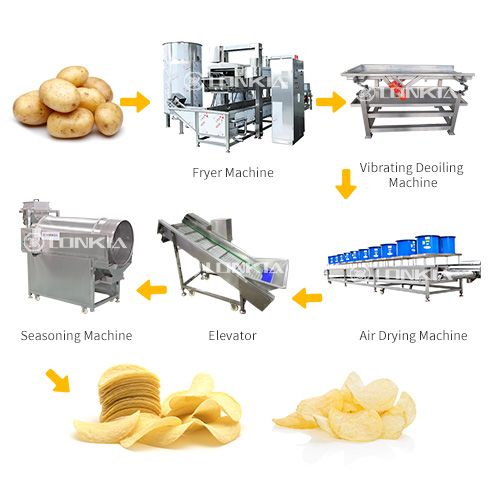

The potato chips production line integrates potato preparation, frying, de-oiling, seasoning, and packaging, ensuring consistent crispiness, flavor, and shelf life. Equipped with precise frying control, and continuous oil filtration, this system maintains 98% uniform chip quality while optimizing oil and energy consumption. This production line is ideal for businesses looking to produce classic, crinkle-cut, thick-cut, or flavored potato chips with maximum efficiency and minimal waste. Suitable for small to large-scale manufacturers, the production line is customizable to meet specific market demands.

1

1

Potato Preparation

2

2

Frying

3

3

De oiling

4

4

Seasoning

5

5

Packaging

Feel free to contact us to getting offer and more information about our Potato Chips Frying Production Line.

Can be expanded at any time to accommodate higher capacities and meet individual requirements

This potato chips production line delivers high-efficiency processing, premium chip quality, and cost-effective operations, making it the ideal solution for snack food manufacturers aiming.

Classic Salted Chips

Ridged Chips

French Fries

Flavored Chips

Have a question on equipment, pricing, parts, service or anything else? We’re here to help.

Contact Us