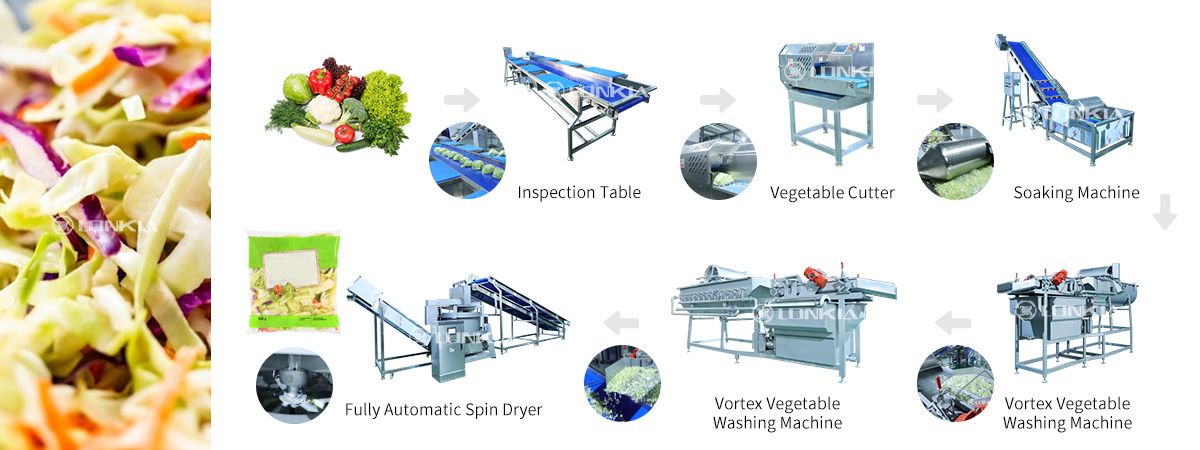

The Vegetable Salad Processing Line is designed for efficient processing of fresh vegetables. This fully automated system integrates manual sorting, precision cutting, deep cleaning, and rapid drying to maintain freshness, texture, and food safety standards. Equipped with an ozone-enhanced vortex washing system and a high-speed centrifugal dryer, this line effectively removes dirt, bacteria, and excess moisture, ensuring optimal shelf life and quality. It is widely used in fresh-cut vegetable processing plants, central kitchens, and supermarket distribution centers.

Processing Output: 100KG-2000KG/H (Customizable)

1

1

Inspection Table

2

2

Vegetable Cutter

3

3

Soaking Machine

4

4

Vortex Vegetable Washing Machine

5

5

Fully Automatic Spin Dryer

Feel free to contact us to getting offer and more information about our Vegetable Salad Processing Line.

Can be expanded at any time to accommodate higher capacities and meet individual requirements

Our salad processing line is widely used in fresh-cut vegetable processing plants, food manufacturing facilities, central kitchens, and supermarket distribution centers.

Mixed Salad Greens

Mixed Salad Greens

Mixed Salad Greens

Mixed Salad Greens

Mixed Salad Greens

Mixed Salad Greens

Mixed Salad Greens

Mixed Salad Greens

Have a question on equipment, pricing, parts, service or anything else? We’re here to help.

Contact Us