The demand for crispy, golden French fries has driven innovation in the food processing industry, leading to the development of advanced automatic French fries production equipment. For businesses looking to produce large quantities of French fries efficiently, investing in this type of machinery is essential. In this blog, we will introduce the key components of an automatic French fries production line, its advantages, and a pricing overview.

Overview of Automatic French Fries Production Equipment

An automatic French fries production line consists of multiple specialized machines working in sync to transform raw potatoes into ready-to-eat or ready-to-cook French fries. These systems are designed for large-scale production with minimal manual intervention, ensuring consistency in quality, size, and texture. Here's an introduction to the essential equipment used in a typical production line:

1. Potato Washer and Peeler

This machine combines washing and peeling, effectively removing dirt and skins from the potatoes. It ensures the raw materials are clean and ready for slicing. For larger production lines, a high-efficiency steam peeler is used for ideal peeling performance.

2. French Fry Cutter

The French fry cutter slices potatoes into uniform strips. Adjustable thickness and different shapes are available. For customers with specific shape requirements, such as crinkle-cut fries or curly fries, specialized machines are offered.

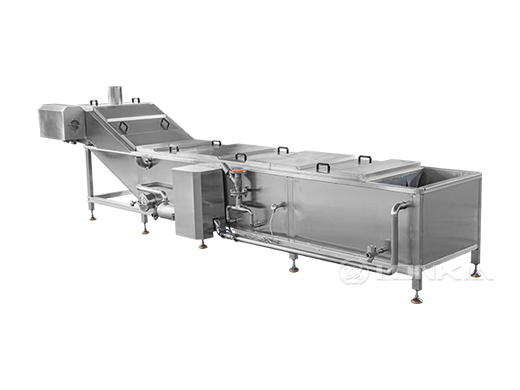

3. Blanching Machine

The blanching machine removes excess starch and preserves the color of the fries. This step is crucial to ensuring the fries stay crispy and golden during cooking.

4. Drying Machine

After blanching, the fries are passed through a drying machine to remove excess moisture, preparing them for frying or freezing.

5. Continuous Fryer

The continuous fryer uses precise temperature control to cook the fries to perfection. These fryers are designed for efficiency, reducing oil consumption while ensuring even cooking.

6. Freezer

For producing frozen French fries, a freezing tunnel rapidly cools the fries after frying, locking in flavor and texture.

7. Packaging Machine

Once the fries are processed, an automatic packaging machine seals them in airtight bags for storage or distribution. These machines can include multi-head weighers to ensure consistent portion sizes.

Pricing Overview

The cost of automatic French fries production equipment depends on capacity, the level of automation, and the specific machines included in the production line. Typically, the following price ranges can be expected:

- Small-scale Production Line: For smaller businesses or startups, semi-automatic production lines come with lower initial investments. These are designed for limited production volumes and may require more manual supervision.

- Mid-range Production Line: For medium-sized manufacturers, the mid-tier French fries production equipment offers high levels of automation at a more moderate price. These systems provide greater capacity and improved efficiency while reducing labor costs.

- Large-scale Production Line: Fully automated, high-capacity production lines for large-scale production typically cost more, as they consist of the most advanced equipment in the industry. Specific customizations, such as real-time monitoring and other advanced features, will determine the final cost.

Investing in automatic French fries production equipment can significantly enhance a manufacturer’s production capacity and consistency. Understanding the range of available machines and their associated costs helps in making an informed purchasing decision. Whether you're a small business or a large manufacturer, we can provide a French fries production line that meets your needs and budget.

For more detailed pricing information or to explore customized French fries production solutions, contact us today!