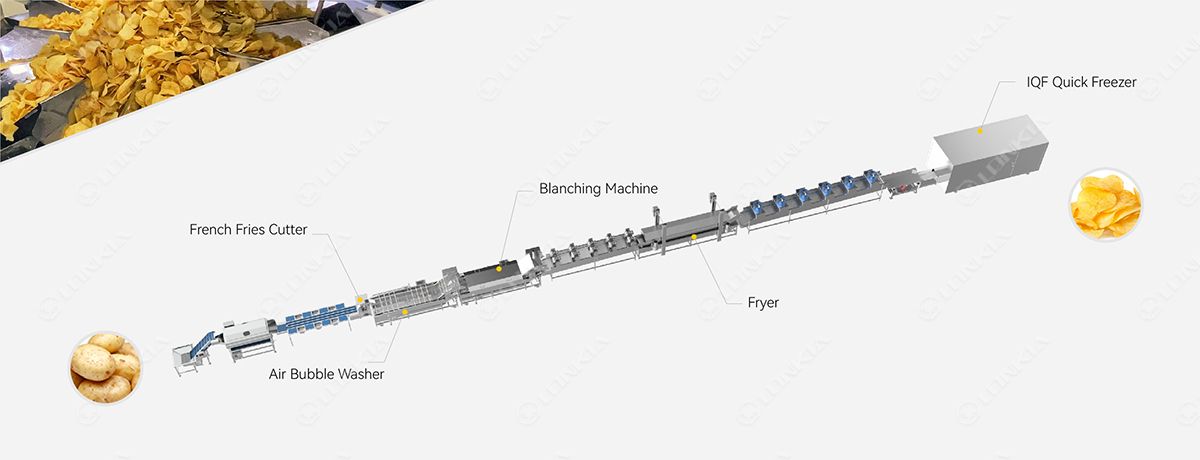

The Semi-Automatic Potato Chips Production Line strikes an optimal balance between automation and manual intervention, making it a cost-effective solution for small to medium-sized enterprises. This line requires a lower initial investment compared to fully automated systems, allowing businesses to optimize production costs while still achieving substantial output. Its compact design is particularly advantageous for facilities with limited space, enabling streamlined operations even in smaller production areas. The line is easily adjustable and scalable to meet varying production needs.

1

1

Peeling

2

2

Cutting

3

3

Blanching

4

4

Drying

5

5

Frying

Feel free to contact us to getting offer and more information about our Semi Automatic Potato Chips Production Line.

Can be expanded at any time to accommodate higher capacities and meet individual requirements

This semi-automatic potato chips production line offers a balance between efficiency, quality, and affordability, making it an excellent choice for small and medium-scale snack food businesses.

Potato Chips

Potato Chips

Potato Chips

Potato Chips

Have a question on equipment, pricing, parts, service or anything else? We’re here to help.

Contact Us