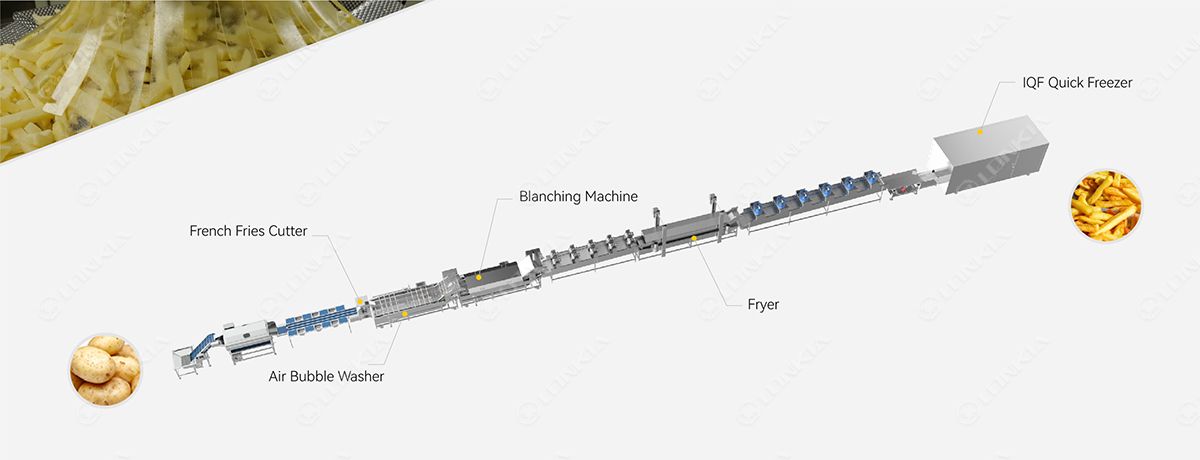

Our Semi-Automatic French Fries Line is a versatile and efficient solution, perfectly suited for mid-sized businesses aiming to scale up operations while maintaining control over the production process. This production line expertly balances automation with manual operation, providing manufacturers the flexibility and precision needed throughout the production process, all while optimizing costs.

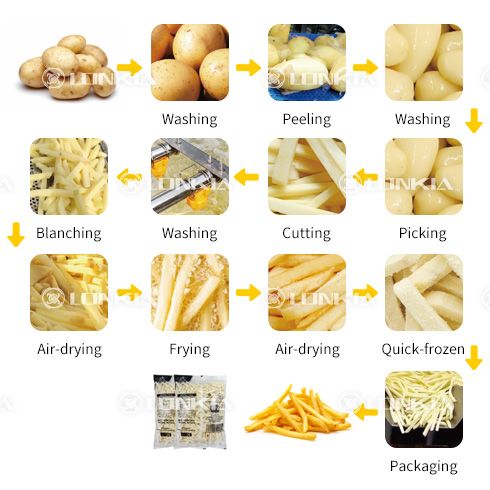

1

1

Peeling

2

2

Cutting

3

3

Blanching

4

4

Drying

5

5

Frying

Feel free to contact us to getting offer and more information about our Semi Automatic French Fries Production Line.

Can be expanded at any time to accommodate higher capacities and meet individual requirements

This semi-automatic French fries production line provides an efficient, cost-effective, and high-quality processing solution for small to medium-scale manufacturers looking to expand in the frozen and fast-food markets.

French Fries

Crinkle-Cut Fries

Sweet Potato Fries

Waffle Fries

Have a question on equipment, pricing, parts, service or anything else? We’re here to help.

Contact Us