Efficient Solutions For Frozen Food Processing

- LONKIA offers Tunnel freezers, Fluidized Bed Freezers, Spiral Freezers & Complete IQF Lines to Help You Boost Productivity and Preserve Quality.

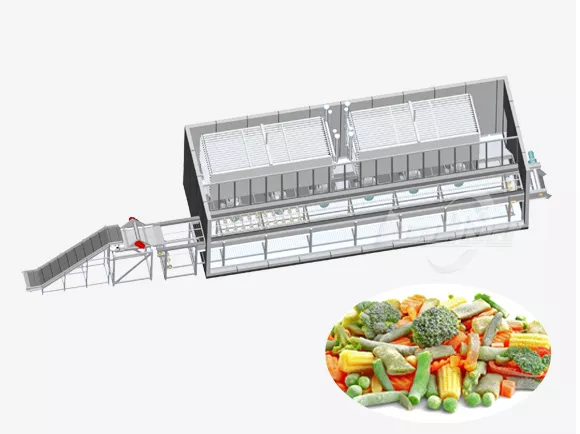

Ideal for freezing fruits, vegetables, seafood, and prepared foods. Using a tunnel-type design and high-speed axial fans, this freezer ensures rapid and uniform freezing at -30°C to -40°C. Perfect for large-scale production with capacity from 300kg/h to 6000kg/h.

Specially designed for granular, diced, or sliced foods such as peas, corn, and berries.Mechanical vibration and airflow allow individual quick freezing (IQF) without clumping.

Compact yet powerful – ideal for high-throughput freezing in limited space. Commonly used for seafood, bakery items, meats, poultry, and dairy.

From single quick freezers to complete IQF production systems, we provide customized solutions for our customers

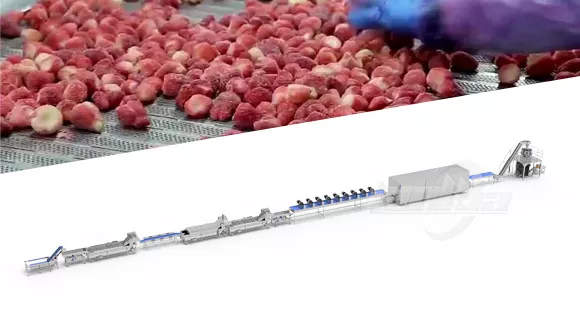

LONKIA seafood quick-frozen processing line integrates advanced IQF (independent quick freezing) technology, which can quickly freeze seafood in a short time and effectively preserve the taste, flavor and nutrition of seafood. The system is highly automated, reducing labor costs, reducing pollution risks, and improving overall production efficiency.

This production line is suitable for a variety of seafood varieties such as fish, shrimp, squid, etc., and can customize cleaning, cutting, quick freezing and packaging solutions according to customer needs. It is an ideal choice for seafood processing companies to expand production capacity and improve quality.

LONKIA quick-frozen vegetable processing line covers key links such as cleaning, cutting, blanching, cooling, dehydration, quick freezing, and packaging. It is suitable for industrial processing of various fruits and vegetables such as peas, carrots, corn kernels, broccoli, green beans, etc.

The entire line is made of food-grade stainless steel and meets international food safety and hygiene standards. It is widely used in frozen food factories, central kitchens and agricultural product export companies. It is an ideal solution for achieving efficient and standardized vegetable processing.

LONKIA quick-frozen fruit processing line integrates cleaning, picking, cutting, blanching, quick freezing, packaging and other processes, and is designed for industrial processing of various fruits such as strawberries, blueberries, mangoes, pineapples, peaches, etc. The entire line is made of 304 food-grade stainless steel, meets international hygiene standards, and is suitable for a variety of production scales and process requirements.

The system is equipped with advanced fluidized bed quick freezing technology and automated control systems, which can freeze fruits to below -18°C in a short time, effectively lock in freshness, and retain the original flavor, color and nutrition. With compact structure, stable operation and low energy consumption, it is an ideal choice for frozen fruit companies to achieve efficient, safe and standardized production.

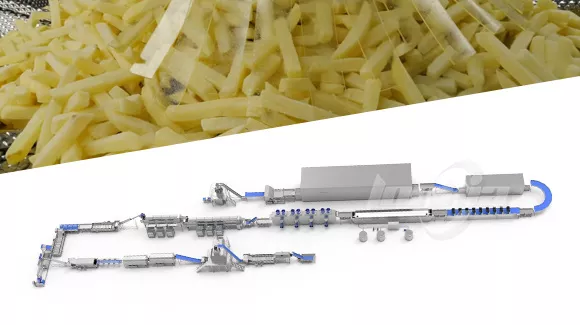

LONKIA Frozen French Fries Production Line integrates washing, peeling, cutting, blanching, pre-frying, de-oiling, quick freezing and packaging, and is designed for large-scale high-quality frozen French fries production.

The entire production line is made of 304 stainless steel and meets food-grade hygiene standards. The production line supports customized configuration and can be flexibly matched with steam peeling machine, continuous frying machine, spiral quick freezer, fluidized bed quick freezer and other equipment to meet different production needs.

To learn more about food freezing production line solutions, please contact our customer service center and our experienced and knowledgeable team of engineers will help you.

Okra

Carrot

Corn

Green Peas

Spinach

Strawberry

Yellow Peach

Blueberries

Raspberry

Banana

Shrimps

Fish

Squid

Meat Patty

Scallops

LONKIA is a food machinery processing and manufacturing enterprise integrating scientific research, production and sales. It provides you with high-quality services, has a high-quality workforce, and has strong design, development and manufacturing capabilities. The products adopt advanced domestic and foreign production technology and parts, and have won the trust and support of customers with novel structure, stable performance, excellent quality and ready-to-use after-sales service.

Professional and Reliable

Have a question on equipment, pricing, parts, service or anything else? We’re here to help.