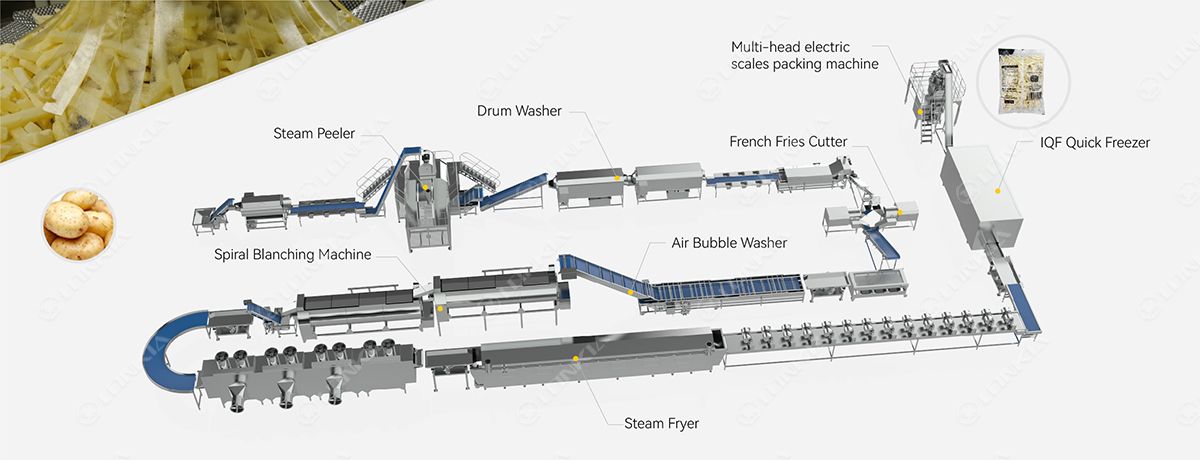

The fully automatic French fries production line utilizes advanced automation technology to achieve fully automated production from raw material handling to finished product packaging, significantly enhancing production efficiency and product consistency. output capacity can be customized from 300kg/h to 1000kg/h according to your needs, while ensuring the crispy taste and rich flavor of the French fries. Capacity:300-10000 kg/h

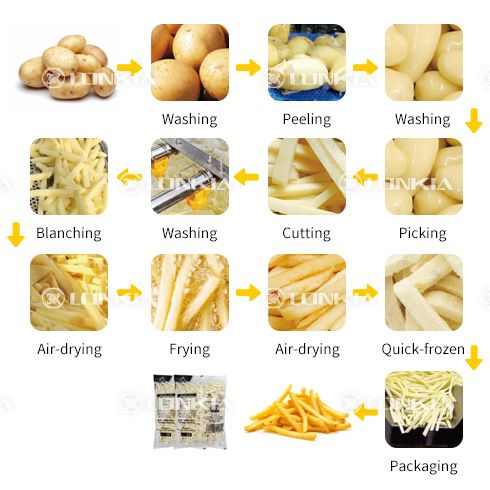

1

1

Peeling

2

2

Washing

3

3

Cutting

4

4

Blanching

5

5

Drying

6

6

Frying

7

7

Freezing

Feel free to contact us to getting offer and more information about our Fully Automatic French Fries Production Line.

Can be expanded at any time to accommodate higher capacities and meet individual requirements

This fully automated French fries production line optimizes costs, efficiency, and quality, helping you stay competitive in the global fast-food and frozen food markets.

French Fries

Crinkle-Cut Fries

Sweet Potato Fries

Waffle Fries

Have a question on equipment, pricing, parts, service or anything else? We’re here to help.

Contact Us