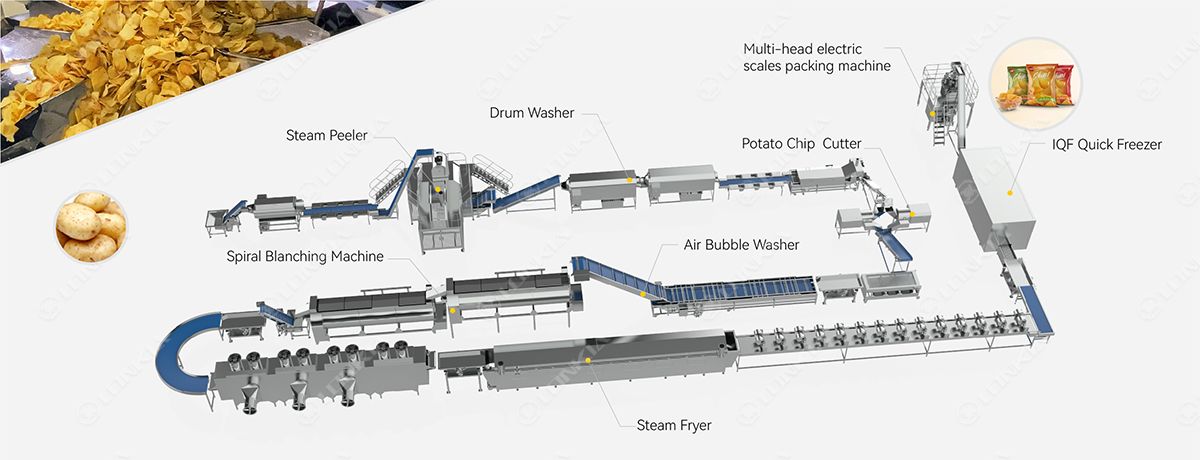

The Fully Automatic Potato Chips Production Line is engineered for high-efficiency processing, designed to meet the growing demand for quality snack foods. This state-of-the-art system automates each stage of production—from raw potato handling to packaging—ensuring minimal labor involvement while maximizing output and product quality. Utilizing advanced technology, this line maintains consistent standards in taste, texture, and appearance, catering to the needs of large-scale manufacturers. Capacity:300-10000 kg/h

1

1

Steam Peeling

2

2

Washing

3

3

Cutter

4

4

Blanching

5

5

Dryer

6

6

Frying

7

7

Seasoning

8

8

Packaging

Feel free to contact us to getting offer and more information about our Fully Automatic Potato Chips Production Line.

Can be expanded at any time to accommodate higher capacities and meet individual requirements

This fully automatic potato chips production line maximizes efficiency, reduces costs, and guarantees superior chip quality, making it the perfect solution for industrial-scale snack food manufacturers.

Potato Chips

Potato Chips

Potato Chips

Potato Chips

Have a question on equipment, pricing, parts, service or anything else? We’re here to help.

Contact Us